Energy

The energy audit is the essential starting point for implementing energy efficiency measures in a building. By analyzing current consumption and technical characteristics, it helps identify the most effective and cost-efficient solutions, estimating potential savings and the investment payback period.

Key Contents

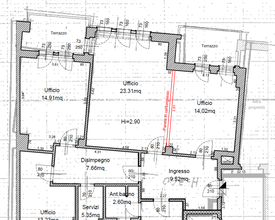

- Building Identification: address, cadastral references, geographic coordinates.

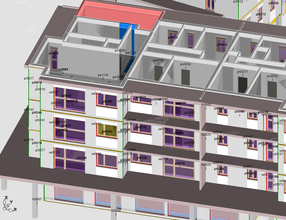

- General Characteristics: intended use, year of construction, number of units, major renovations.

- Regulations and Methodology: UNI standards, calculation assumptions, site inspections.

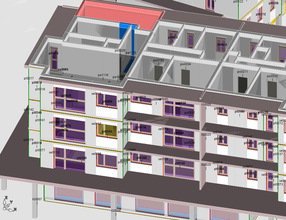

- Technical-Energy Analysis:

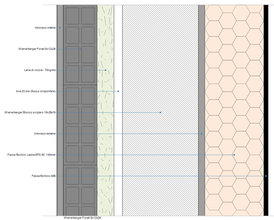

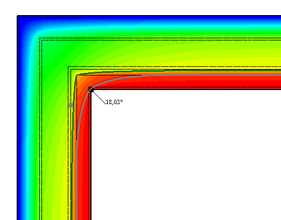

- Geometry and building envelope (layers, windows, thermal bridges)

- Systems: heating, cooling, domestic hot water, lighting, renewables

- Management and maintenance practices

- Energy Balance: seasonal energy demand and performance of individual services.

- Actual Consumption: analysis of energy bills and supply contracts over the past 3 years, highlighting discrepancies (e.g. vacant units or alternative heating systems).

- Critical Issues: identification of the most energy-intensive services and inefficiencies.

- Improvement Measures:

- Upgrades to envelope and systems

- Installation of renewable energy sources

- Replacement of high-consumption appliances

- Evaluation of comfort, maintenance, costs, and emissions

The audit must include at least one proposal for improving the building envelope and three for the systems, unless technical or regulatory constraints are duly justified.

The Energy Report, required under Italian Law no. 10 of 1991, must be prepared in the following cases:

- New building construction

- Renovation works

- Volume expansions

- Replacement of climate control systems (e.g. boiler, heat pump, etc.)

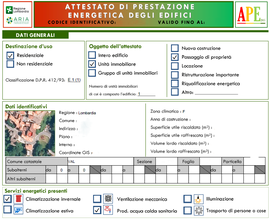

The procedure developed over the years to certify buildings as quickly and efficiently as possible—refined through the experience of over 300 energy certificates issued in the Province of Como—is as follows:

- Initial contact with the client: by phone and/or email

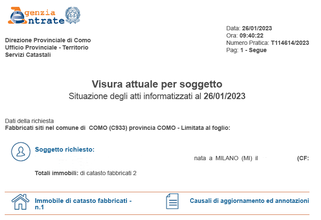

- Collection of preliminary property information:

- Owner’s details (full name, tax code)

- Cadastral floor plan or project layout (including any cadastral records)

- Boiler manual or contact details of the condominium administrator (if heating is centralized)

- On-site inspection of the property to be certified, including any verification measurements and photographic documentation

- Calculation of energy performance using validated software (Logical Termolog EPix)

- Completion of the certificate via the regional portal and delivery of the generated document to the client

- Delivery of the Energy Performance Certificate (APE) in duplicate, stamped and signed in original, either by registered mail or collection at our office

Once the inspection date is agreed upon, we take care of collecting and organizing all the necessary documentation to complete the process.

Thermography is a technique used to detect electromagnetic radiation emitted by bodies in the infrared spectrum. It relies on radiometric measurements performed with specialized digital cameras (thermal imagers), which—through optical sensors—capture thermal radiation at every point of the framed surface and convert it into temperature data.

In civil applications, thermography serves to qualitatively document and characterize buildings and structures in their physical condition (degradation and conservation), guiding—when necessary—further targeted investigations. These are essential in understanding the built environment and supporting the correct design of restoration, maintenance, and rehabilitation interventions.

Applications of Thermography in Construction

- Detection of masonry texture, hidden voids or cavities, and embedded metallic or wooden elements

- Verification of detachment or loss of adhesion in plasters and coatings

- Identification of thermal bridges and energy dispersion in buildings

- Localization of heating systems under floors, within walls or ceilings, and structural elements

- Verification of correct installation of thermal insulation systems (e.g. external cladding or cavity fill)

- Detection of material inconsistencies in building components

- Assessment of humidity and condensation issues

- Identification of leaks or faults in hydraulic, thermal, or electrical systems

- Detection of water infiltration in waterproofing layers

- Mapping of structural elements (beams, pillars, slabs, metallic or wooden components)

- Monitoring of degradation phenomena and analysis of building pathologies

- Quality control and verification of construction works